Low-emission non-flammable composite structures

High-strength composite structures characterized by low weight, complete corrosion resistance, electrical conductivity or insulating properties, and fire resistance or UV resistance.

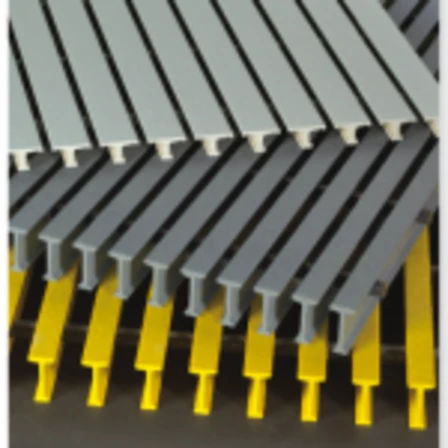

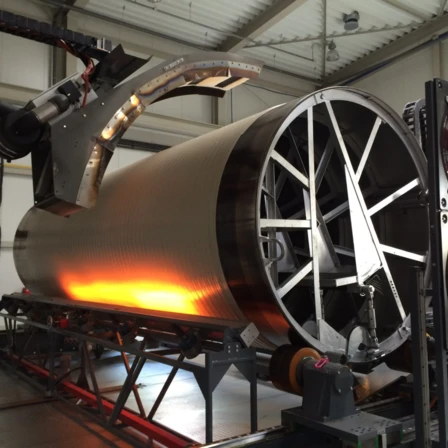

Pultrusion is a continuous manufacturing method for thermosetting profiles reinforced with fiberglass. The term comes from the English words "pull" (to draw) and "extrusion," and it refers to the production of profiles by pulling glass fibers saturated with resins according to the NKG formula through a shaping system that gives them the appropriate shape, followed by thermal curing.

Composite profiles produced by the pultrusion method consist of polyester resins that are reinforced with glass fibers, with the addition of a flame retardant and an antistatic agent.

The pultrusion production method is essentially fully automated, although the phase of developing the appropriate mixture for specific technical requirements and preparing the molds can take several months or even years. Hence, the developed composition of glass roving, polyester resin, flame retardant, and graphene nanorods that meet the requirements for flame resistance, antistatic properties, and non-toxicity, created by KG Consulting Krzysztof Gregorek, is abbreviated as NKG, which stands for New Mining Composite.

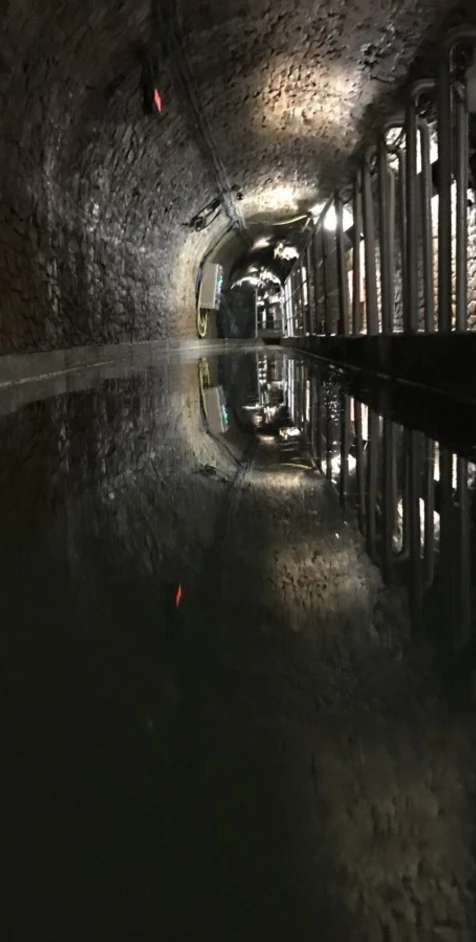

The NKG New Mining Composite material is a raw material intended for use as a basic material for manufacturing composite structural elements used in the mining industry, specifically in coal, potassium salt, and copper mines. It serves as a flame-resistant, antistatic, and non-toxic material that meets the requirements according to the following standards:

-

PN-EN ISO/IEC 80079-38: 2017-02 Explosive atmospheres – Part 38: Equipment and components for use in explosive atmospheres occurring in underground mining operations.

-

PN-EN ISO 80079-36: 2016-07 Explosive atmospheres – Part 36: Non-electric equipment for explosive atmospheres – Methodology and requirements.

-

PN-G-46222:1997 Mining shafts and ladder compartments. Requirements and tests.

Products manufactured using the pultrusion method are characterized by excellent mechanical properties.

Properties of NKG

- Low specific gravity (1.75 g/cm³).

- Thermal insulation.

- Electrical insulation.

- High chemical resistance (does not oxidize and is very resistant to acids).

- Does not produce sparks during grinding and cutting.

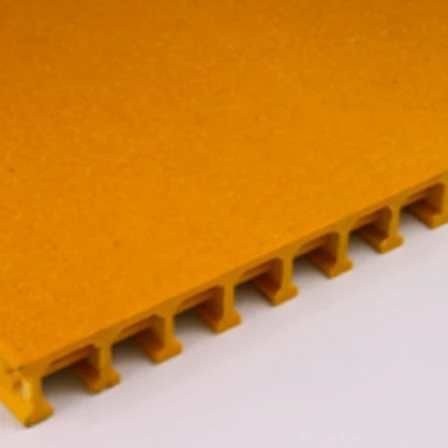

- Possibility of bulk coloring (full RAL color range).

- Resistance to UV radiation.

- Durability of colors.

Applications of NKG

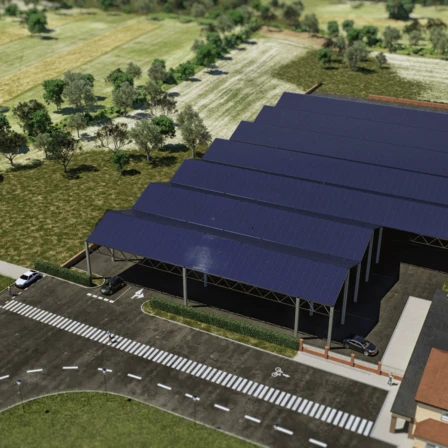

- Structural Profiles: Durable, corrosion-resistant, and lightweight, they perform excellently in harsh industrial conditions.

- Ladders: Lightweight, durable, available with a safety basket. Suitable for use in explosion-risk zones.

- Safety Barrier Systems: Sturdy and aesthetic, easy to install, tailored to the specific needs of the client.

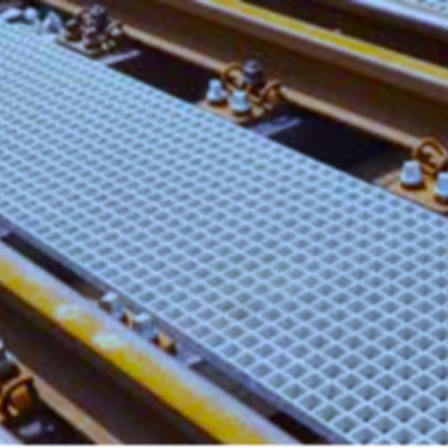

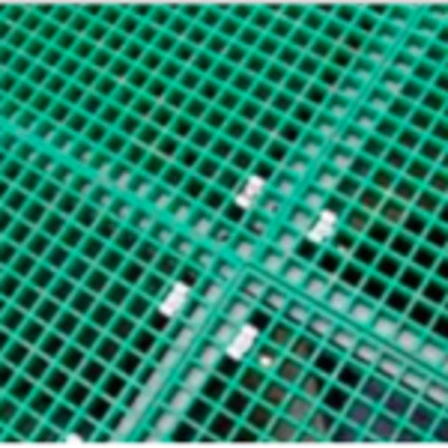

- Grates: Durable and resistant to wear. They are mainly used in areas where good ventilation, resistance to heavy weight, and intense traffic are essential, such as in mines and industrial facilities.